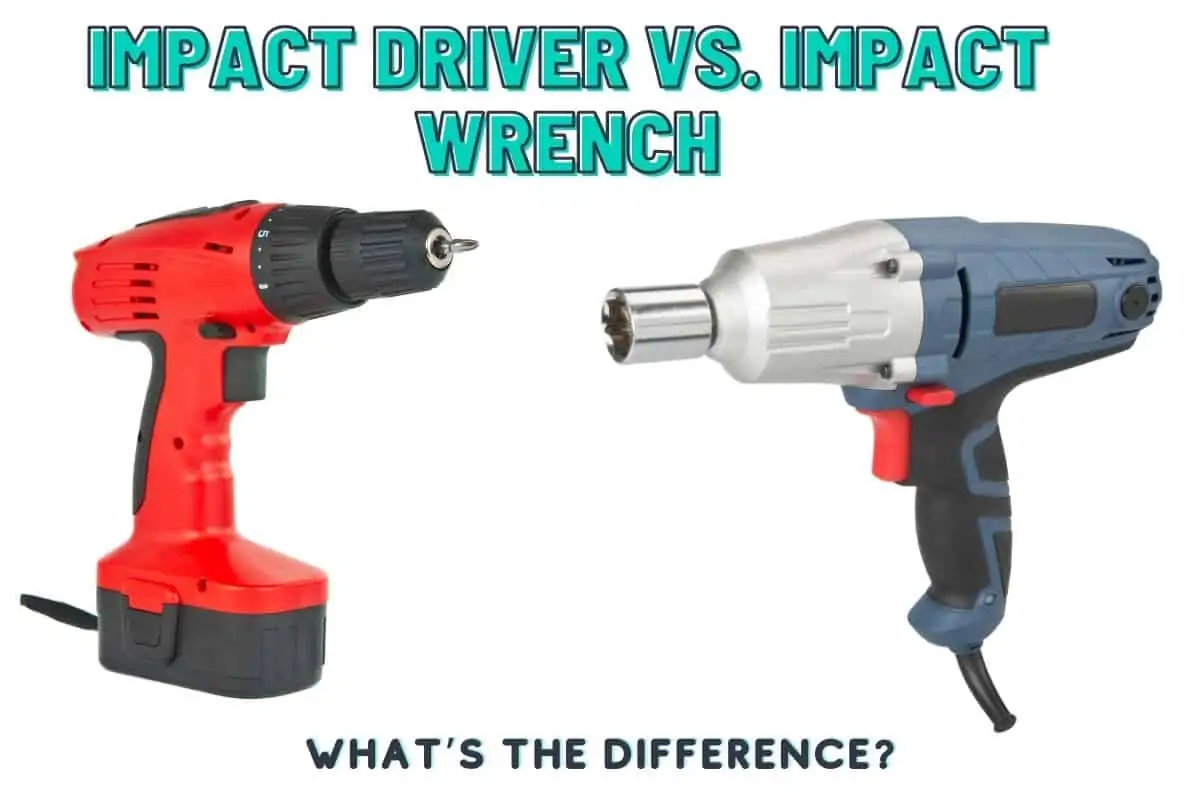

Impact drivers and impact wrenches are popular tools, and there are thousands of models to choose from. If you’d like to understand the difference between impact drivers vs impact wrenches, to determine which one to buy, here’s a comprehensive guide.

You can use impact wrenches and impact drivers for everyday DIY and hobbyist tasks such as fastening, drilling, removing nuts, and driving. It’s also possible to achieve greater accuracy, better results, and comfort than what’s afforded by torque wrenches and power drills.

Impact Drivers

Impact drivers are a popular power tool that produces a high amount of torque and a strong, repetitive, rotational force, rather than a constant forward force.

Such power allows you to drive in big screws or bore big holes quickly, powerfully, and with relative ease.

If you attach specialist bits to the driver, you can also use it as a power drill. The tool has a 1/4” hex drive socket into which you place bits that have been designed to withstand the additional stress of impact drivers.

The benefit of this tool lies in its power and efficiency. It is more powerful than cordless drills and can drive in fasteners or screws much quicker because of the combination of percussive power and rotational power.

Impact Driver Uses

You can use impact drivers for two primary tasks: loosening and tightening fasteners that require high rotational torque; and drilling holes in hard materials using bits fixed to the driver via hexagonal shanks.

It’s possible to drive long self-threading screws into hardwood effortlessly, whereas a standard cordless drill would struggle. Stripped fasteners or screws are also not a problem for impact drivers.

If you want to see an impact driver in action, this slow-motion footage video will interest you.

Drilling holes using the 1/4” hex shank and drill bit is another common use for this tool. You’ll have few problems drilling holes into wood, aluminum, or plastic.

You can expand the uses even further by using various adapters, if, for example, you want to drill holes into hardwood or heavy metal. Bits rated explicitly for impact drivers and such materials, however, are essential.

Impact Driver Power Sources

Both corded and cordless impact drivers are available. However, the most common tend to be cordless, either 12V or 18V/20V max.

The main benefit of a cordless model is portability. You can take it wherever you go and even work at heights if necessary.

On the downside, you will need to make sure your batteries have sufficient power. If the battery power gets low, you’ll experience a lack of power. Batteries also need to be regularly replaced as over time the safety and performance of them will be reduced.

Another issue is that they don’t like heat in any way. If you use it to drive lots of fasteners or screws in rapid succession, it may malfunction. It’s best to allow the tool to sit for a moment between tasks or switch to another cordless impact driver.

A corded model can stay cooler for longer because they don’t use a battery and have better gear reduction systems. However, a significant disadvantage is that they can be cumbersome to lug around, and the length of the power cord restricts your workspace.

Impact Driver Torque

Compared to impact wrenches, you can expect less torque from impact drivers. Generally speaking, it will be in the 1500 to 1800 in-lbs of torque range.

Does the amount of torque matter? Yes, it does, because you can have too much. Too much torque could mean you drive the screw or fastening too deeply. It can also lead to a loss of control and accuracy, ultimately damaging your work surface.

Impact Driver Speed

The opposite applies when it comes to comparing speed, as drivers typically have higher speeds than impact wrenches. You can expect a good driver to max out at around 3,600 RPM.

Impact Driver Pros and Cons

Let’s look at the advantages and disadvantages of owning an impact driver. It’s going to help you decide which is better for you.

Impact Driver Pros

- Comfort: Impact drivers are easier on your wrists and causes much less stress and fatigue.

- Powerful: It can power screws and fasteners into dense materials effortlessly and undo stuck or tightly-fitted bolts.

- Versatile: Not only is it useful in driving fasteners and screws, but you can also use it to drill holes.

- Simple to operate: The tool’s size means you can use it with one hand.

Impact Driver Cons

- Heavy-handed: If you’re working on precise or delicate tasks, an impact driver might not be the tool for the job.

Impact Wrenches

Impact wrenches are a specialty tool that has several names. You’ll also find it referred to as an impact gun, air wrench, air gun, and a rattle gun. It’s an essential tool in the arsenal of many professionals, and it can also be useful to have in the home garage.

If you’re an avid auto repair enthusiast or maintain your machinery, there could be a place for this tool in your toolbox. However, it is more expensive than most impact drivers, so you’d need to use it regularly if you want it to pay for itself.

It’s an excellent tool for driving a range of nuts and bolts, most commonly lug nuts, that require a vast amount of rotational force, for example, removing wheel nuts when you want to change a tire.

The mechanism of an impact wrench hammers against the output shaft and the result is a massive amount of torque.

This tool has a similar role to impact drivers but stands out because of its power and force. It’s more powerful than a regular cordless drill and an impact driver put together.

The automotive industry uses impact wrenches extensively for removing and tightening lug nuts. You can also find them in the metalworking industry and production assembly lines.

For a closer look at the air-powered impact wrench’s internal working, spend a few minutes watching this video.

Impact Wrench Uses

Changing tires is the most common use for this tool, but it’s also widely used in heavy equipment assembly, manufacturing of machine tools, construction projects, and automobile assembly.

There are several tasks you can use it for around the home. Securing a TV wall mount or your bed and putting up garden decking are just two examples. You could also use it if there’s rusted nuts and bolts that no other tool can budge.

Minimal effort is required if you use this tool because it stores its energy in a rotating mass and then delivers it suddenly to the output shaft. There aren’t that many home-related jobs you can use it for because of its power.

You can adjust the wrench’s speed using a dial or switch, and you have to make sure you attach the right size socket. Apart from that, all that’s left is to pull the trigger.

Impact Wrench Power Sources

Impact wrenches can be either air-powered or electric (corded or cordless). Air-powered wrenches are more popular with mechanics and professional tradespeople. This tool allows them to work continuously, safe in the knowledge that their power supply will not run out midway through a job.

A pneumatic impact wrench is also popular because it tends to be more powerful and lighter to use. While it’s likely to be less expensive than electric models, don’t forget you’ll have to add the cost of a compressor and hose into your calculations.

There are several dangers associated with pneumatic tools, for example, getting hit by one of the tools attachments. Therefore it is important to check the tool is fastened securely to the air hose.

For DIY projects and around the home, electric impact wrenches are more than powerful enough for most applications. Cordless is the obvious choice if you’re looking for a tool that’s more portable and if you haven’t got access to an air compressor.

Impact Wrench Torque

On the whole, you can expect more power, or torque, from an impact wrench when you compare it with impact drivers. Figures start at around 100 ft-lbs (1200 in-lbs) of torque and can go as high as 1000 ft-lbs (12,000 in-lbs) and even higher.

For home use, such as changing a tire, aim for an impact wrench with around 200 ft-lbs. Torque of 400 ft-lbs and more are a better investment for a professional mechanic, for example.

When it comes to torque, you’ll sometimes find manufacturers referring to something called “nut-busting torque.” This figure relates to the amount of fastening force the impact wrench can remove. It is often lower than standard torque figures. Check the model’s manual for actual specifications.

Impact Wrench Speed

You can expect a good cordless impact wrench to max out at less than 2,000 RPM, which is much slower than an impact driver. Pneumatic impact wrenches, by contrast, regularly hit 8,000 RPM or more.

Impact Wrench Pros and Cons

If you’re still undecided about the virtues of an impact wrench, a quick look at the pros and cons might help you off the fence.

Impact Wrench Pros

- High-powered: An impact wrench delivers greater impact and torque than an impact driver.

- Flexible: You can choose between corded, cordless, or pneumatic, depending on your situation.

- Adaptable: It’s possible to customize this tool by adding different attachments, making it more useful for DIY projects.

Impact Wrench Cons

- Cumbersome: Impact wrenches tend to be heavier, which makes them more challenging to use.

- Expensive: Some of these impact wrenches are costly, which can be a disadvantage if you’re on a tight budget.

- Safety issues: An impact wrench shouldn’t be used for long periods of time because of the danger of vibration exposures.

Impact Driver Vs. Impact Wrench FAQs

If you’re still feeling overwhelmed about the differences between an impact driver vs impact wrench, the following common questions might help you with your decision.

Can You Use an Impact Driver to Remove Lug Nuts?

Yes, you can remove lug nuts with an impact driver. That being said, the lug nuts do have to be tightened at the right amount of torque (80 to 100 ft-lbs). The output torque of the impact driver also has to be greater than 100 ft-lbs.

When it comes down to it, frozen, rusted, or over-torqued lug nuts aren’t going to break loose if you’re using a cordless impact driver. It doesn’t have enough power.

An impact wrench is really not the right tool for the job. You’d be better off using an impact wrench.

Should You Use an Impact Wrench to Tighten Lug Nuts?

It is possible to use an impact wrench to tighten lug nuts, but it’s not usually recommended. The reason behind this is that there’s a risk of using too much torque. If you do this, you could potentially strip or stretch the threads.

Another problem with using an impact wrench is that the torque is difficult to control and manipulate. There is a significant risk of over-tightening the lug nuts.

The best tool for this type of job is a torque wrench instead of an impact wrench. When you tighten bolts, fasteners, and wheel nuts doing it manually allows you to control the torque setting better.

When Should You Not Use an Impact Driver?

An impact driver does have its limitations. Precision, for example, is not its strongest point.

You should limit this tool’s use to projects where placement or the size of a hole is not so crucial compared to the amount of torque required.

Hard materials, such as brick or concrete, can be very challenging for an impact driver if you’re drilling. A more suitable tool would be a hammer drill.

Do You Need Special Sockets for an Impact Wrench?

Your work is going to be better if you use special sockets. You can use standard or regular sockets, but they are likely to break or crack because they are made from a brittle material.

Impact sockets tend to be surface-hardened, which allows them to absorb sudden changes in torque. A regular socket could warp out of shape because it is made using softer steel.

Does an Impact Driver Need Special Bits?

Many impact driver users believe special bits work better, but it’s not always the case. To help you decide which bits are best, let’s take a look at the materials used to make them.

Standard bits use hardened material, which increases wear resistance and allows the bits to last longer. On the flip side, the hardened material is also more brittle and not the best option for a hammer action tool such as an impact driver.

Bits that are rated for impact drivers don’t go through a hardening process. Therefore they are more ductile and able to resist the forces of an impact tool easily.

Another feature that makes a difference is the design. Impact-rated bits have 2” insert bits and a 1/4” quick-change hex. There will be a slender shaft covered in a rubber sleeve that connects the two.

The slender shaft works as a calibrated spring absorbs the impacting action, and better delivers the torque. Such bits are also less likely to shatter.

What is the Difference Between a Cordless Drill and an Impact Driver?

You can use a cordless drill and an impact driver for similar sorts of jobs, but you can’t substitute one for the other. The drill offers lower rotational torque, whereas an impact driver combines a fast-paced rotational strike with higher torque.

Another difference is that an impact driver doesn’t have a clutch like a drill. Its lack of a clutch means it’s a shorter tool and can fit into small spaces that the drill would struggle to manage. Not having a clutch also limits the number of bits you can use and the ease with which the tool takes them.

An impact drill works very effectively when muscle and additional torque are needed, for example, driving long sheetrock screws, in shop furniture, construction deck building, and cabinet installation.

For a more delicate and precise touch, a cordless drill ticks all the boxes.

Impact Driver Vs Impact Wrench – So Which is Best For Me?

So, impact Driver Vs Impact Wrench, how did they stack up? Whatever task you’re undertaking, it’s crucial to have the right tool for the job.

Both impact drivers and the wrenches are designed with specific functions in mind, but if you’re going to be doing many DIY projects or renovating your home, you’re probably going to make better use of an impact driver.

An impact wrench offers much more power but is more specialized and better suited for working with cars or heavy construction materials. It’s also more likely you’re not going to use it regularly, which doesn’t apply to the driver.

I’d love to hear what you decided, and if you’d like to add anything further, please leave a comment below.